Spectral Coating

Spectral coloring modifies the surface of the material, allowing inoxnet® cable products to be elegantly colored in shades of black while retaining their precise shapes, flexibility and robust color durability.

Process Description

Spectral coating is an electrochemical process in which no dyes or

pigments

are applied to the stainless steel surface, but rather the

transparent

chromium oxide layer of the stainless steel is built up. The

interference

effect of the light is used for the coloring: depending on the

chromium

oxide layer thickness achieved, the composition of the light

spectrum and

the viewing angle, different color effects develop. However, it

should be

noted that due to variations in the electrochemical process, the

color

results may differ based on the material and surface properties of

the

workpieces. Thus components like ropes, ferrules, fittings or frames

may not

be exactly same color.

Spectral-colored stainless steel surfaces do not age, do not get

bleach out

or peel off, they are corrosion resistant, and can withstand

temperatures up

to 200° C.

The spectral coating process requires a longer duration compared to

alternative methods. It's essential to note that the product

shipment

timeline will be extended to approximately 6-8 weeks, considering

this

additional processing duration.

Advantages / disadvantages

- Long-Lasting

- Remains the flexibilty of stainless steel cable mesh

- Do not peel off or bleach out

- Shades of black ( may differ at each individual product)

- High Lead time – 6-8 week

Application possibilities

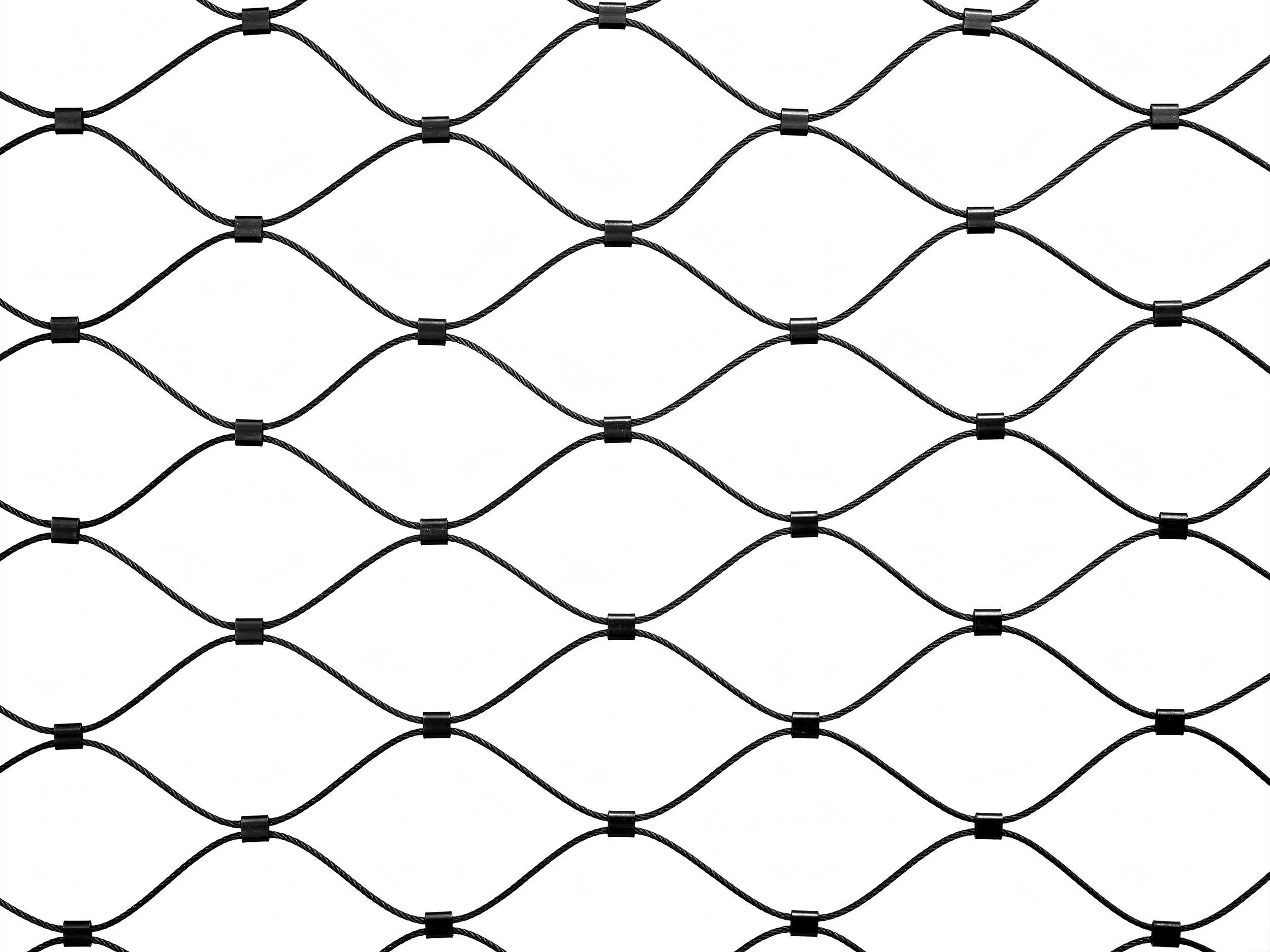

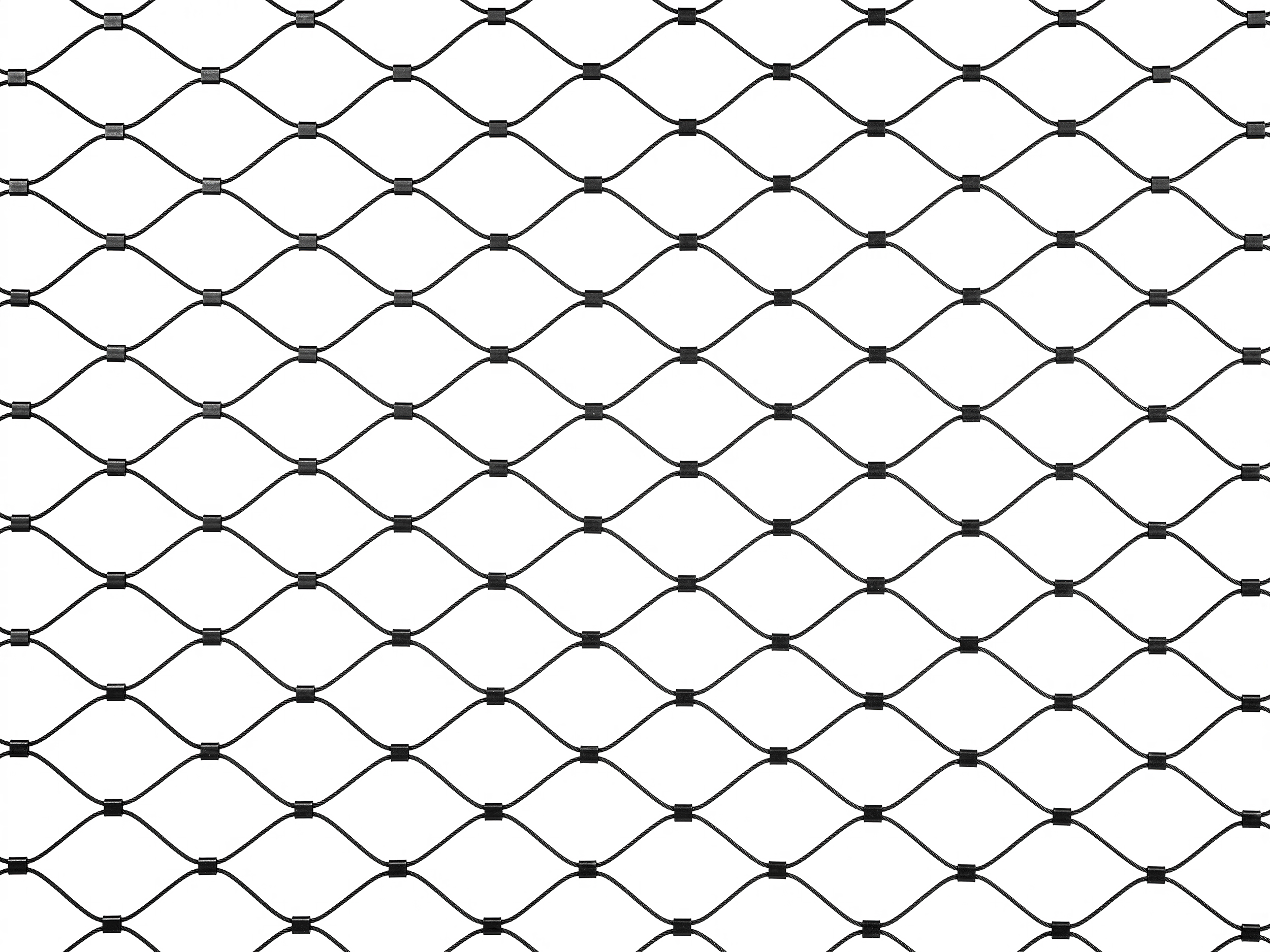

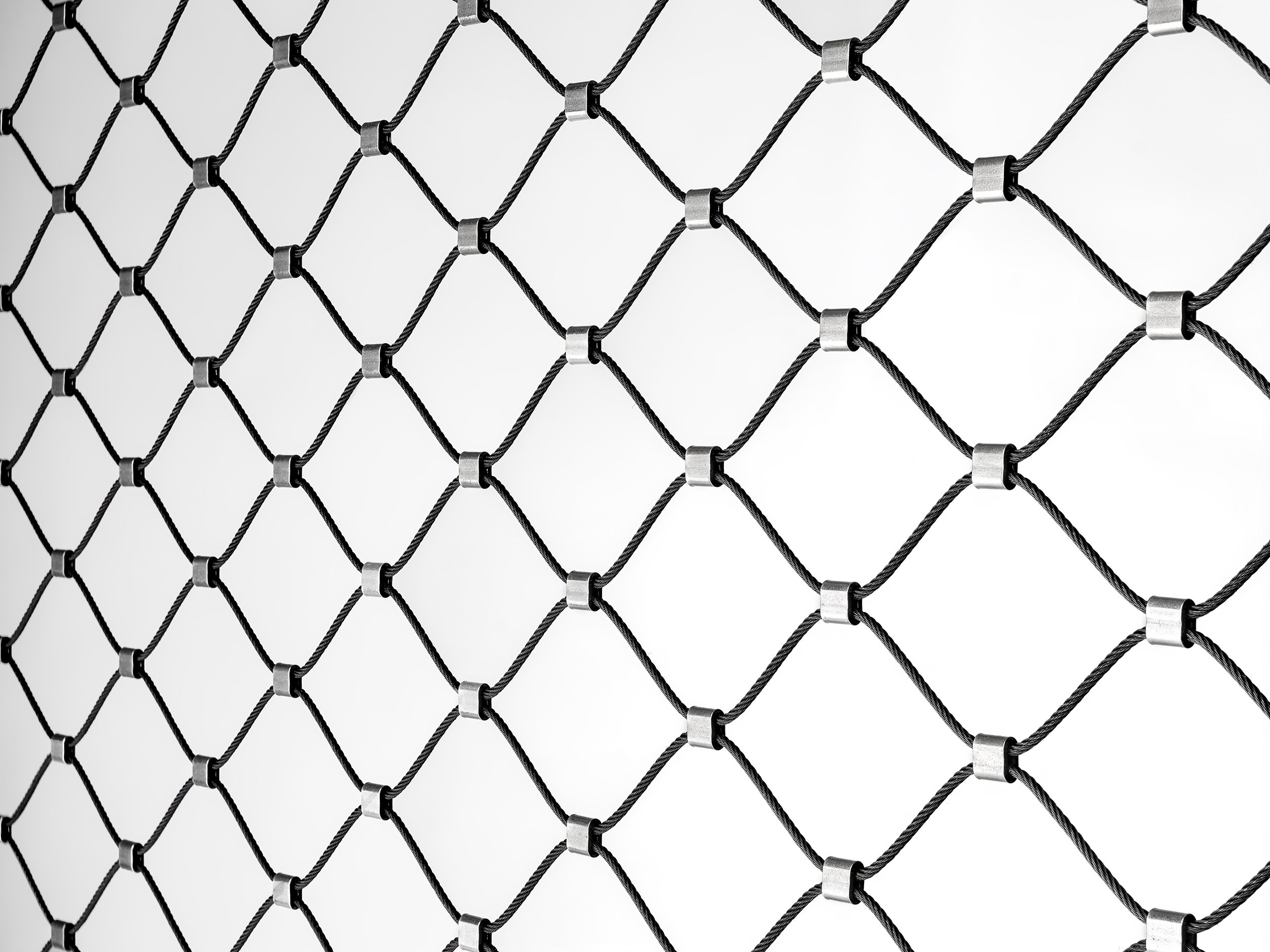

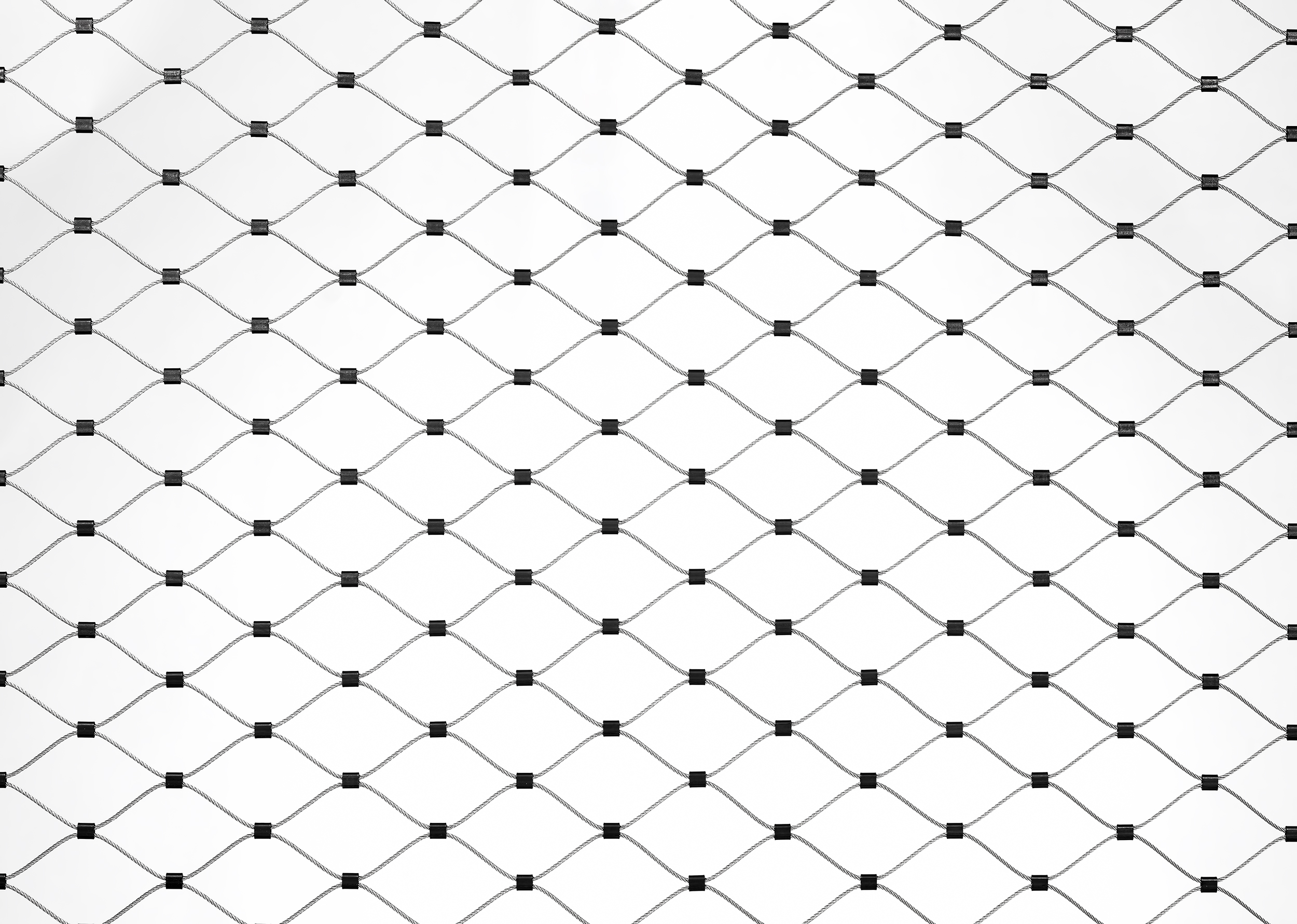

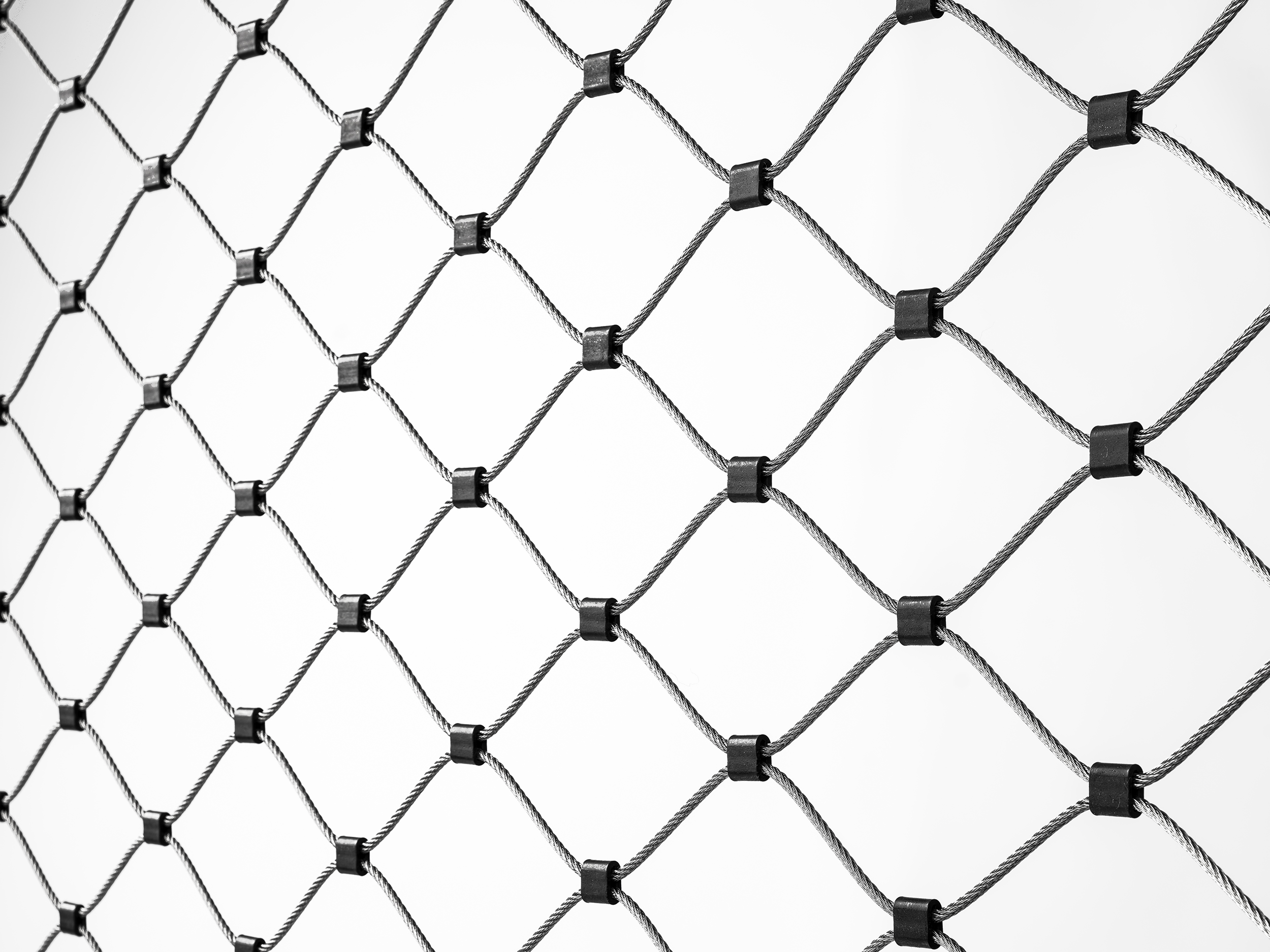

- All in Black I-NET®

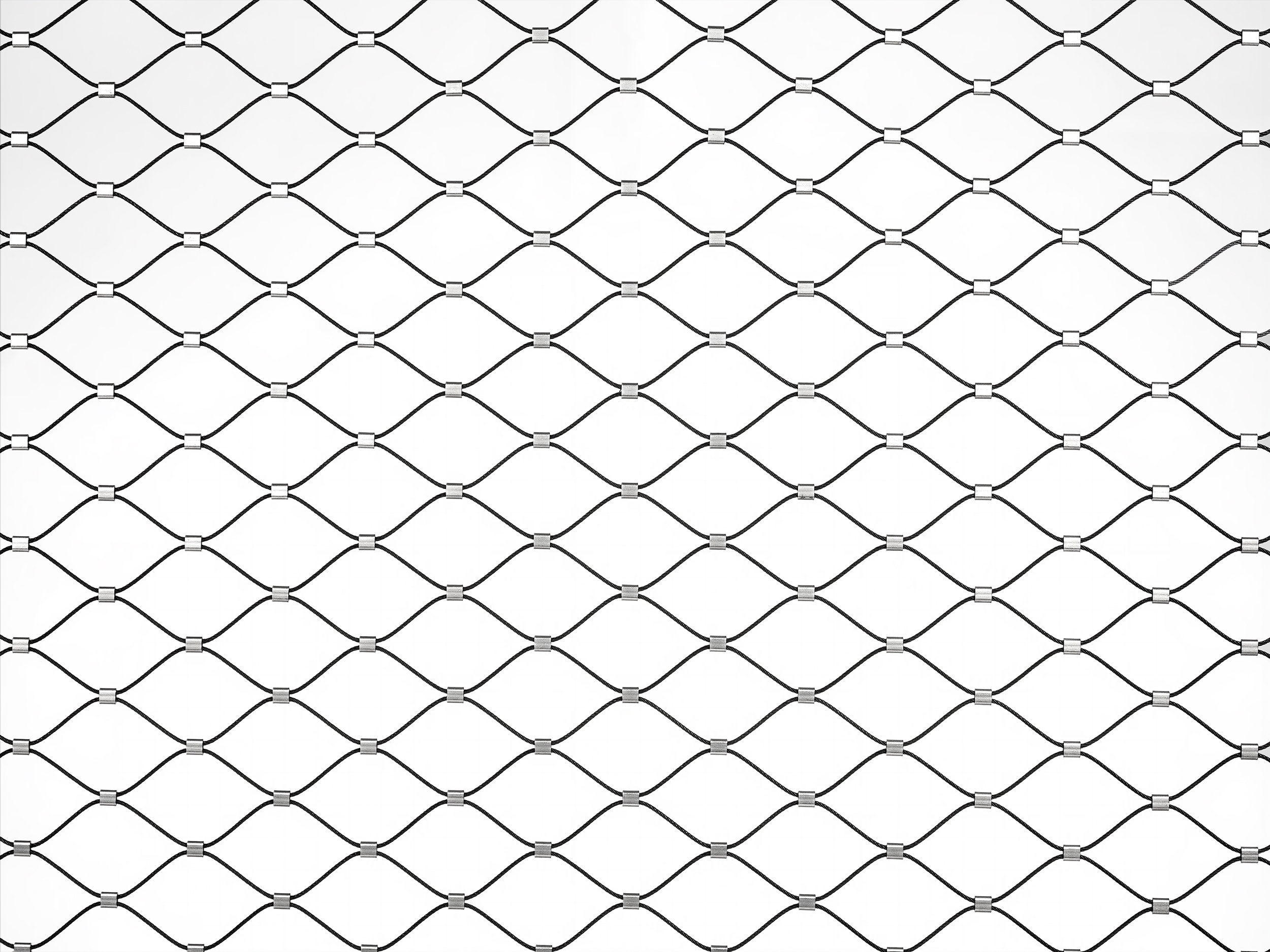

- Cables in Black, Ferrules in Natural Stainless Steel Color

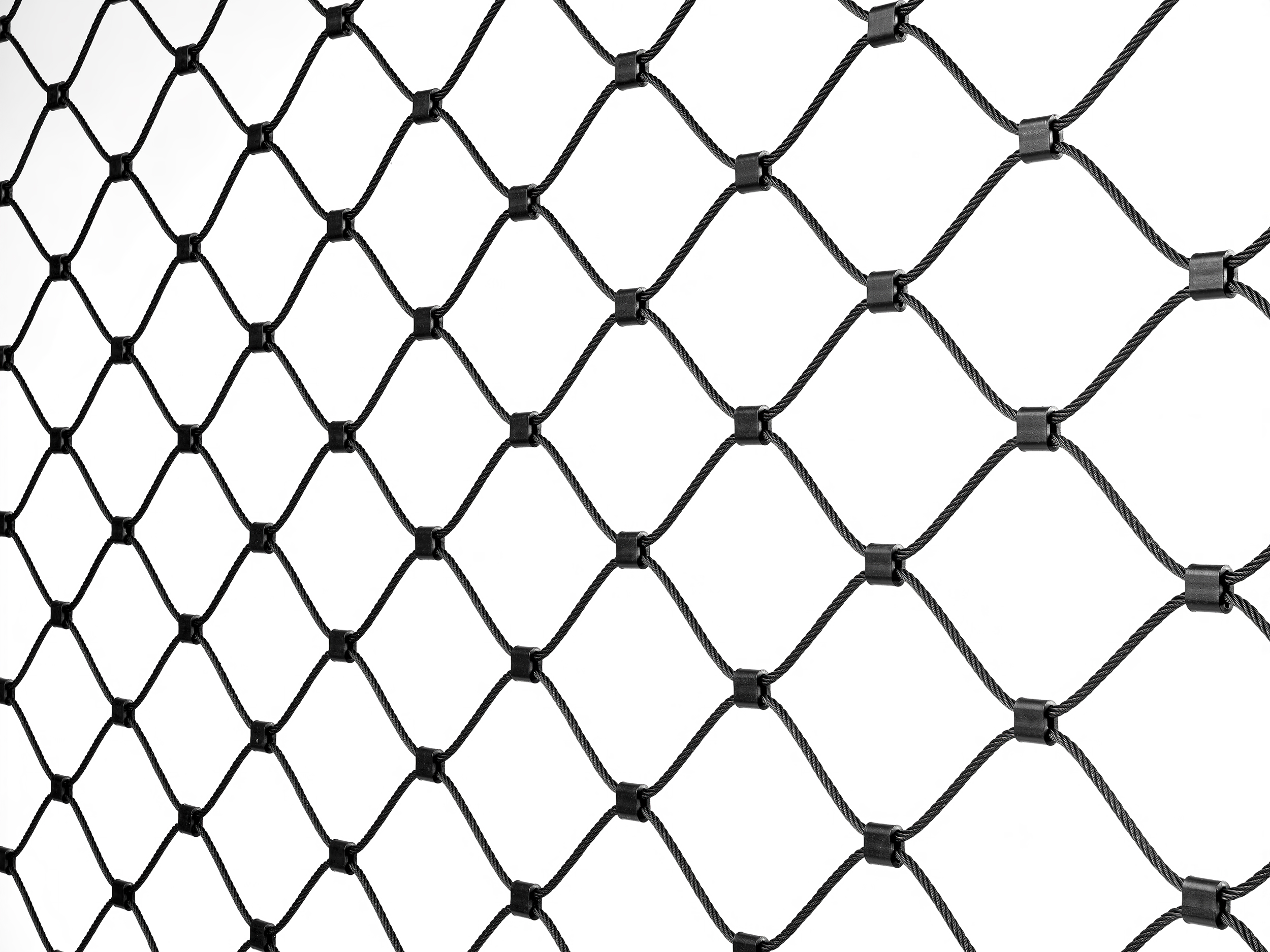

- Entire System in Black; I-NET®, I-ROPE® and Frame Border System

- I-NET® in Black, Frame in Natural Stainless Steel Color