Black Oxide

Black oxidizing is one of the processes which preferred to be applied when it is desired to

get an aesthetic matte black finish besides the corrosion resistance benefits of the stainless

steel products.

Process Description

Black oxidizing, also known as chemical blackening, is a process that doesn't involve the

application of additional materials. Instead, a very thin layer of stainless steel undergoes

modification in a salt immersion bath at approximately 400°C, resulting in a matte black

appearance on the surface. This natural oxide layer enhances the protective properties of

stainless steel mesh while providing visual appeal.

Quicker outcomes achieved compared to spectral coating but still should be noted that the lead

time will increase approximately 3-4 weeks. It provides a cost-efficient alternative to spectral

black coating.

Advantages / disadvantages

- Long-Lasting

- Resistance to weathering and aging

- Remains flexibilty of I-NET®

- Constant Matt black finish

- Lead time – medium, 3-4 weeks

- Cost efficient when compared to Spectral coatings

- Ecological, and elegant looking, it has a strong decorative function.

Application possibilities

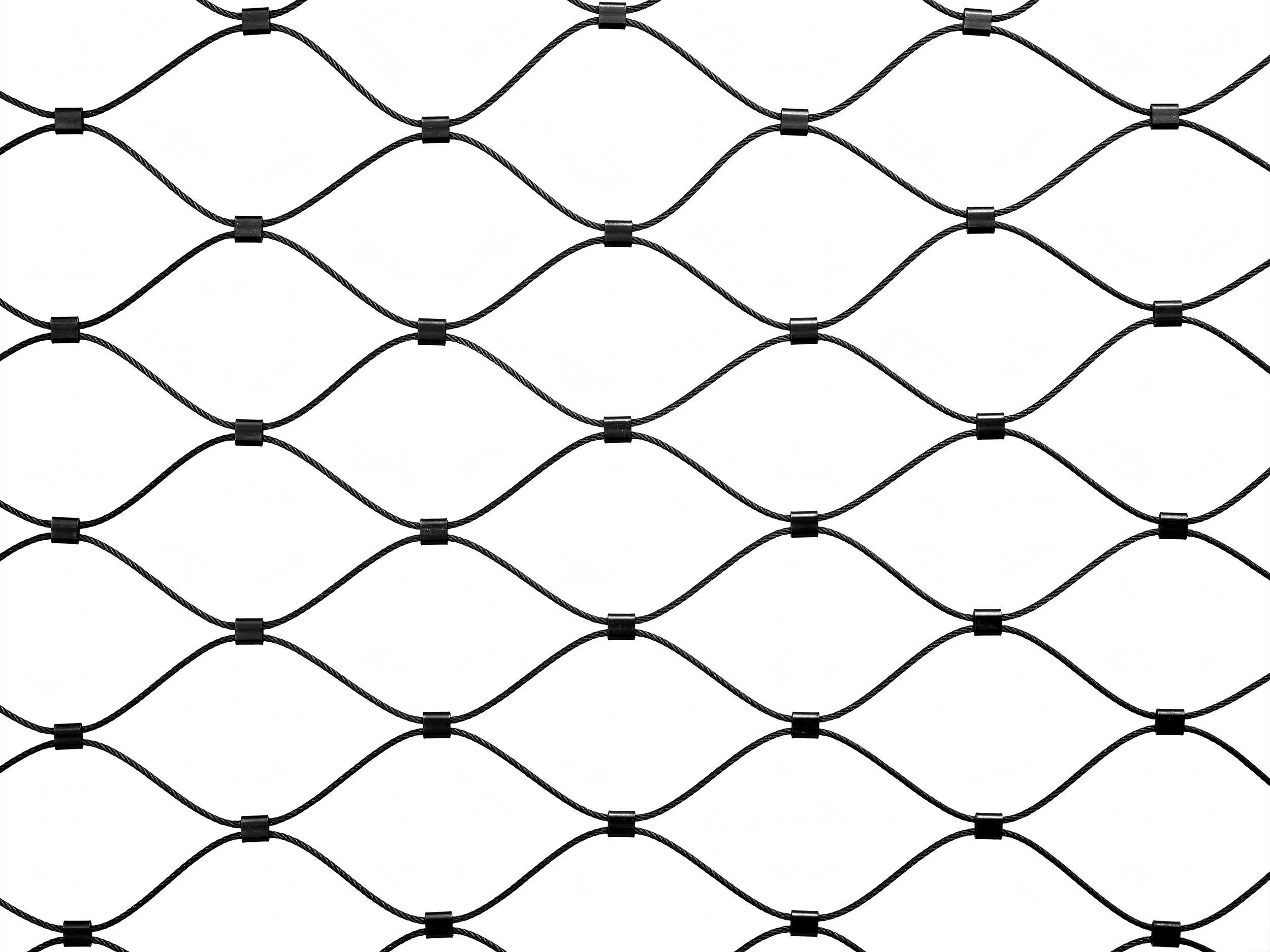

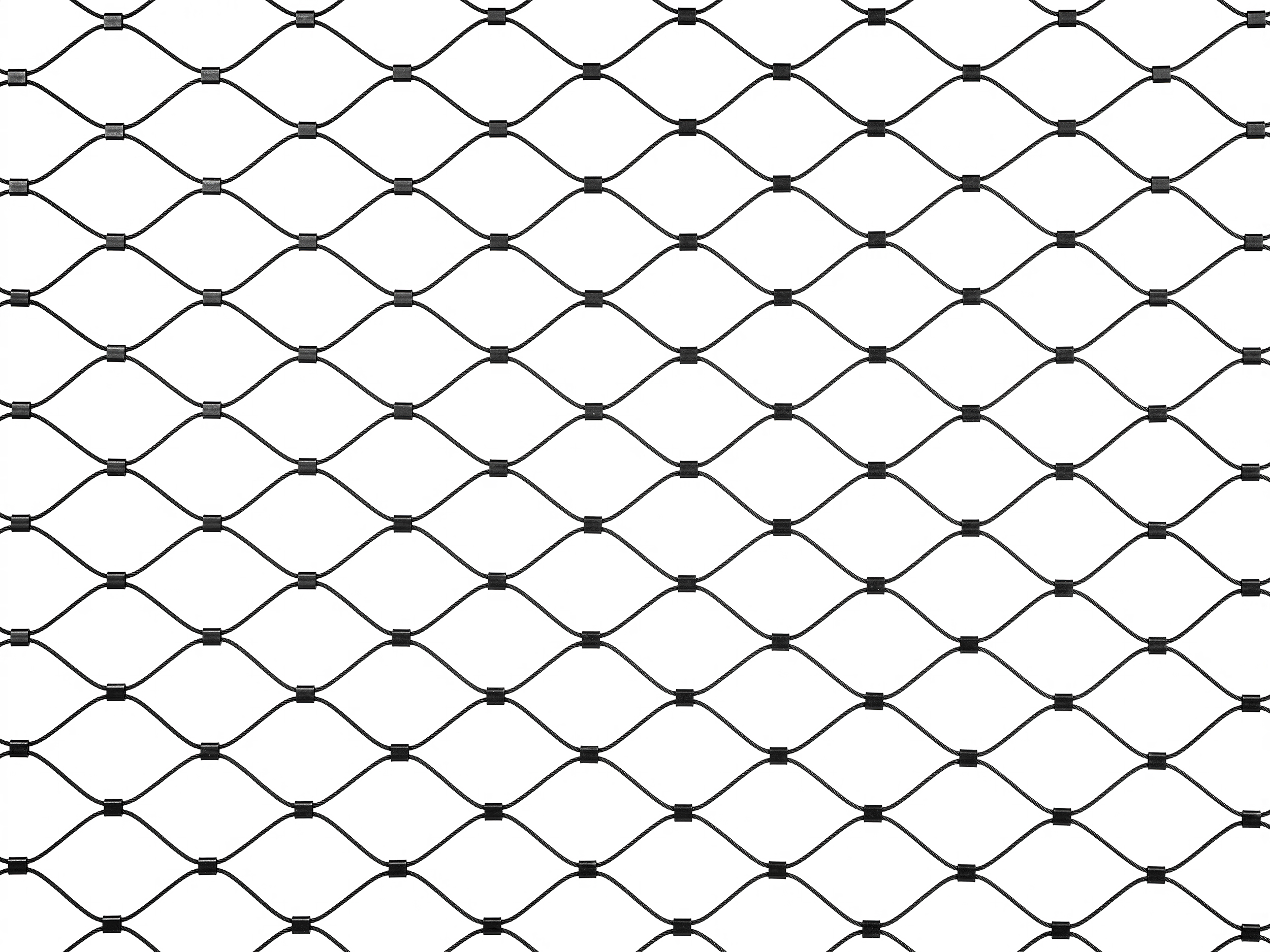

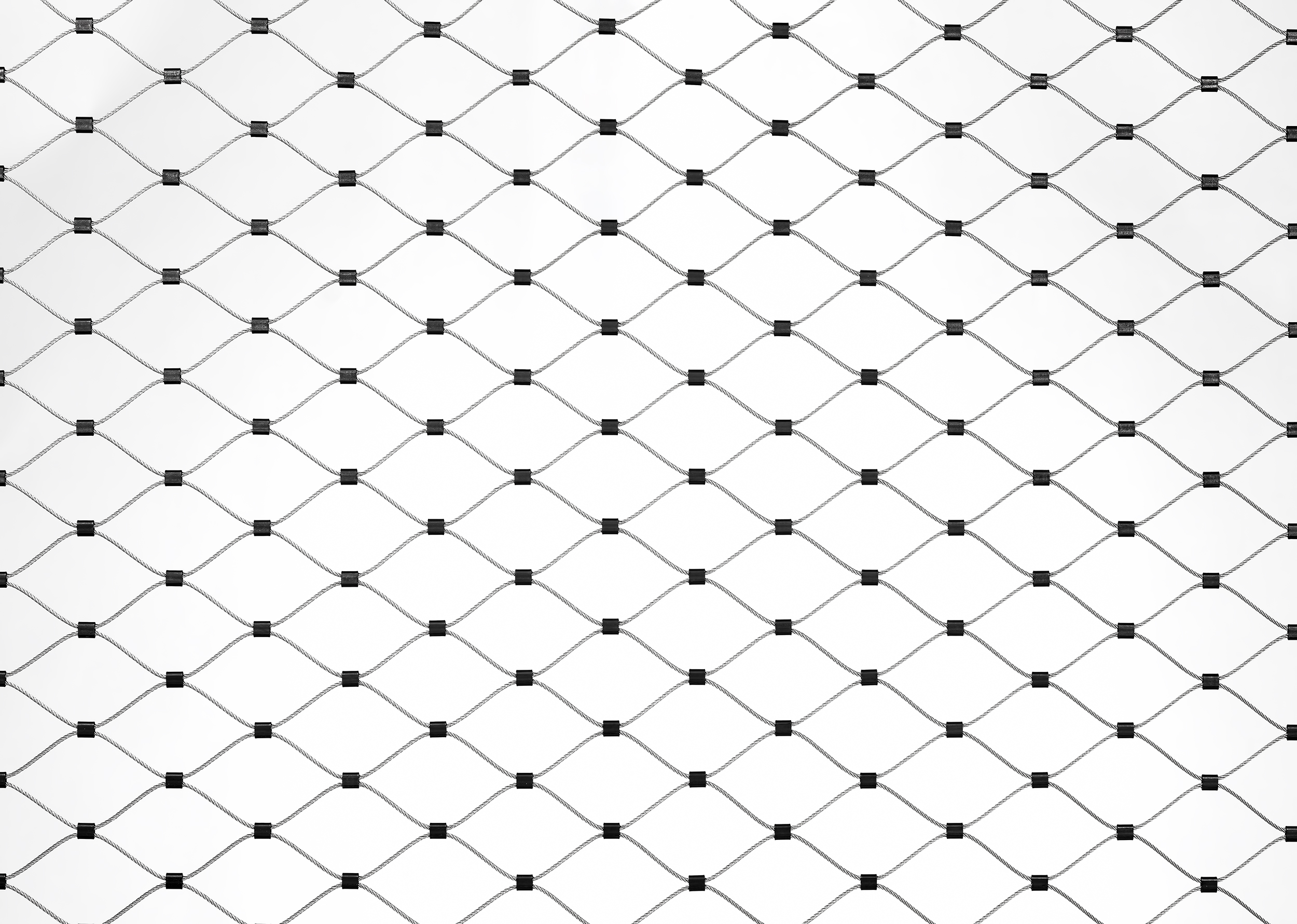

- All in Black I-NET®

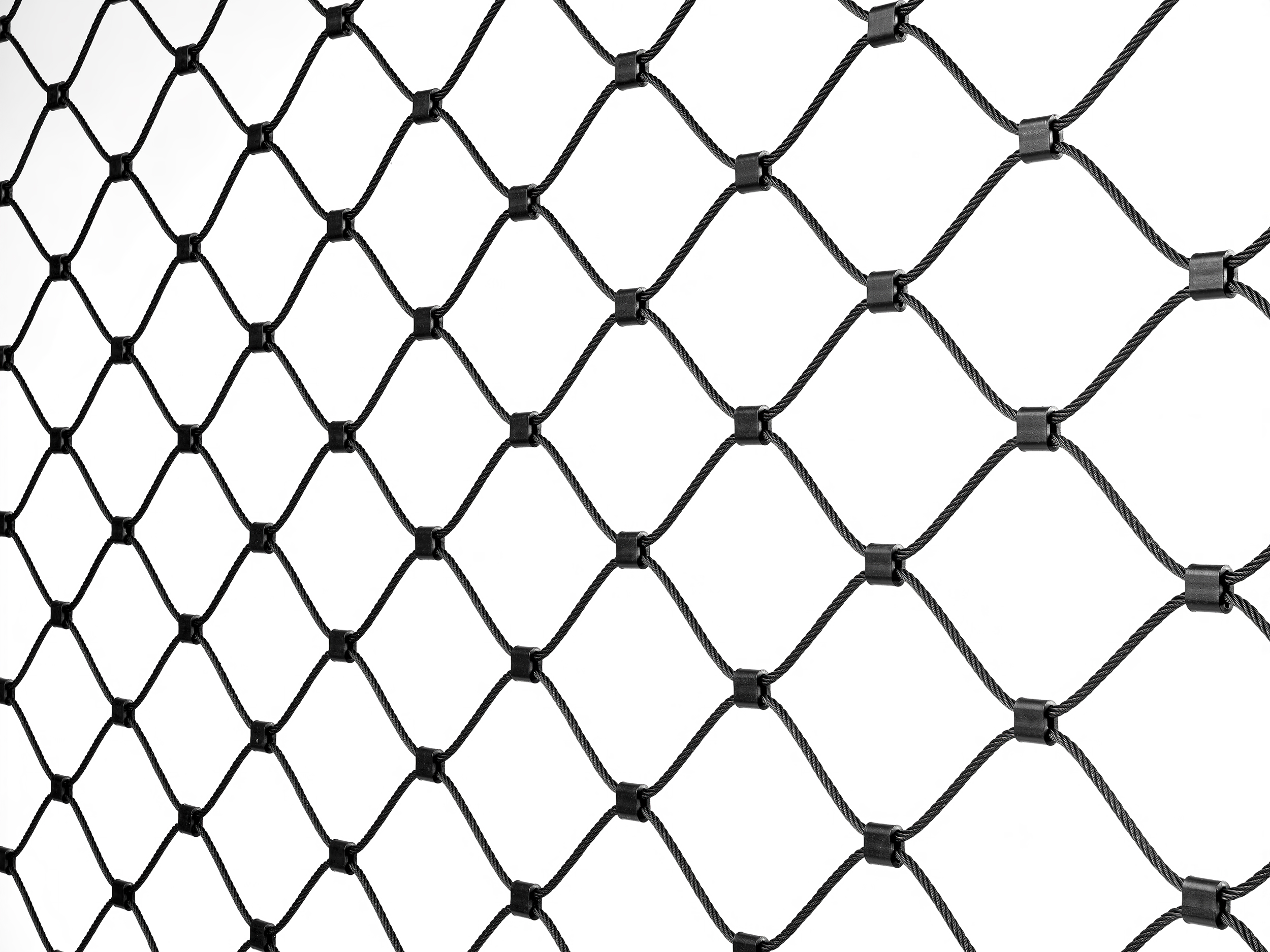

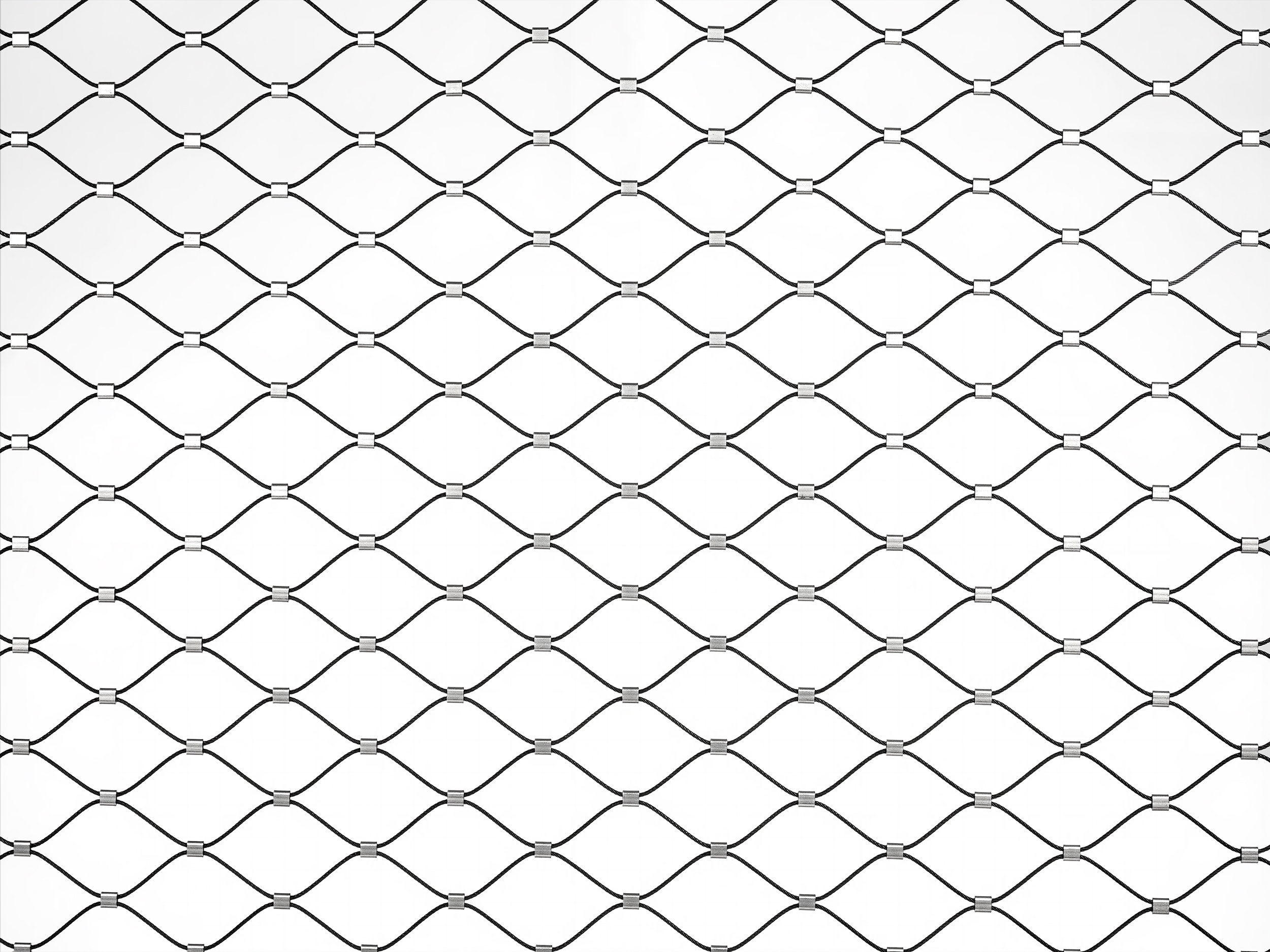

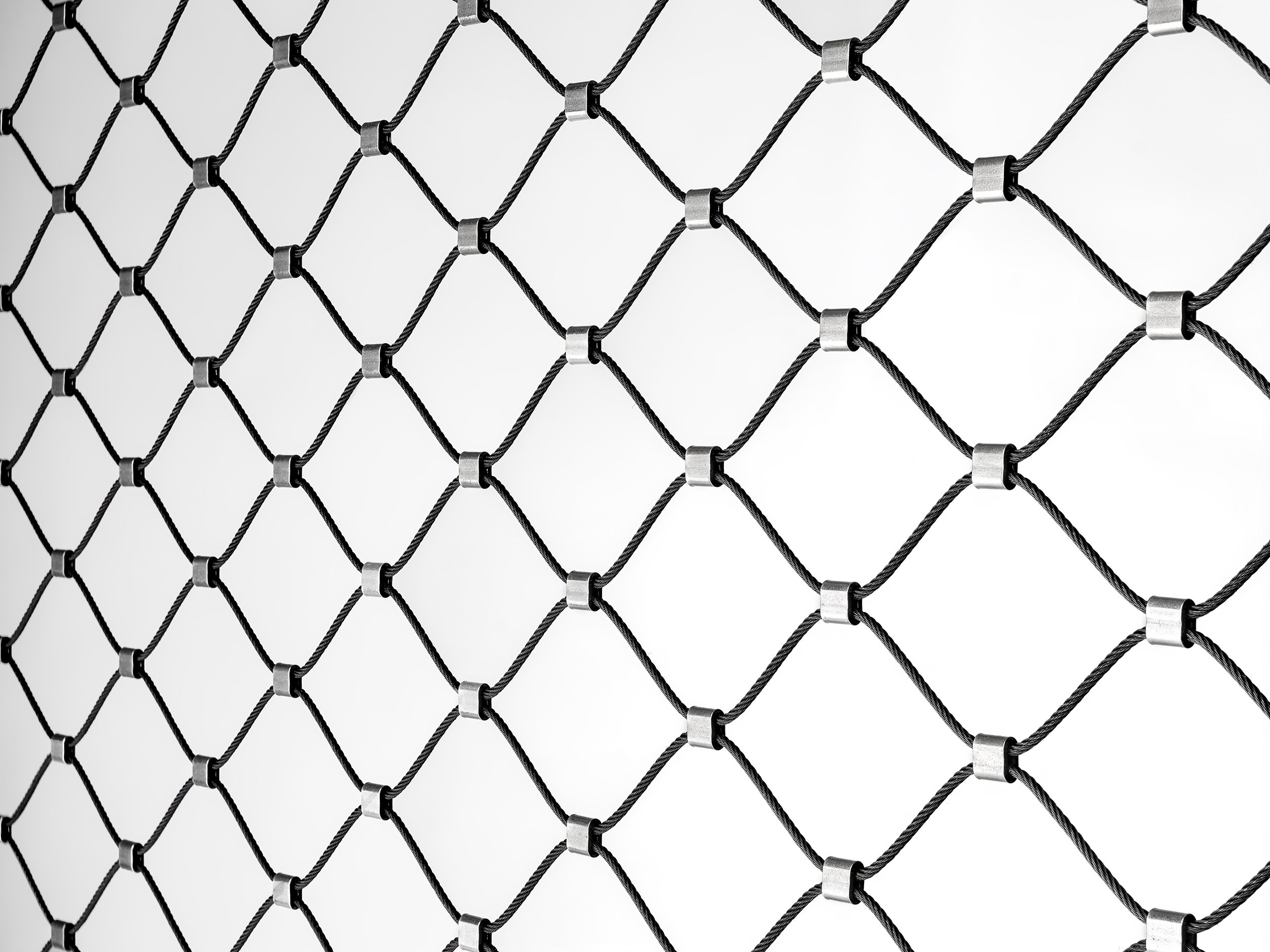

- Cables in Black, Ferrules in Natural Stainless Steel Color

- Entire System in Black; I-NET®, I-ROPE® and Frame Border System

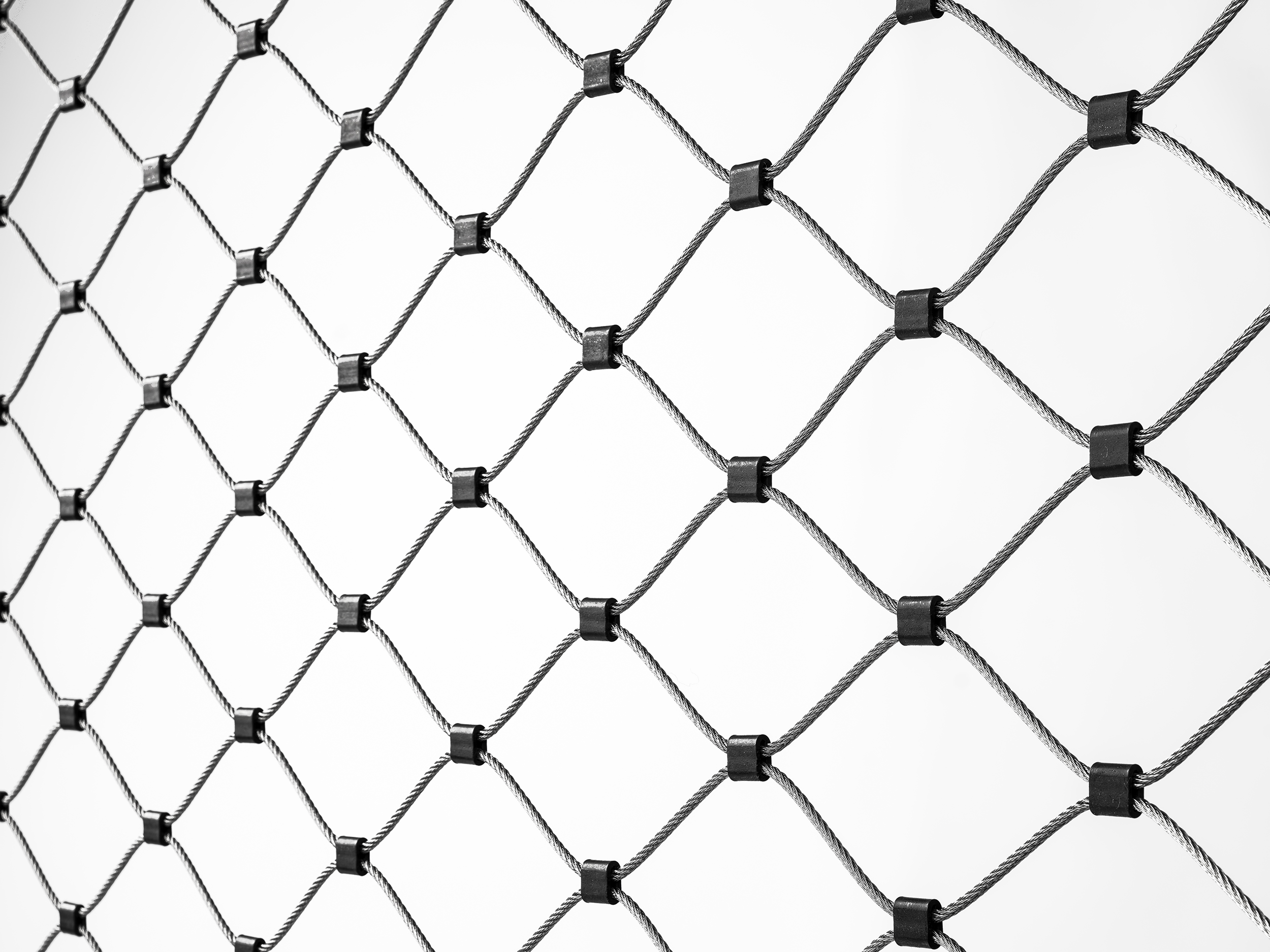

- I-NET® in Black, Frame in Natural Stainless Steel Color