Wet Painting

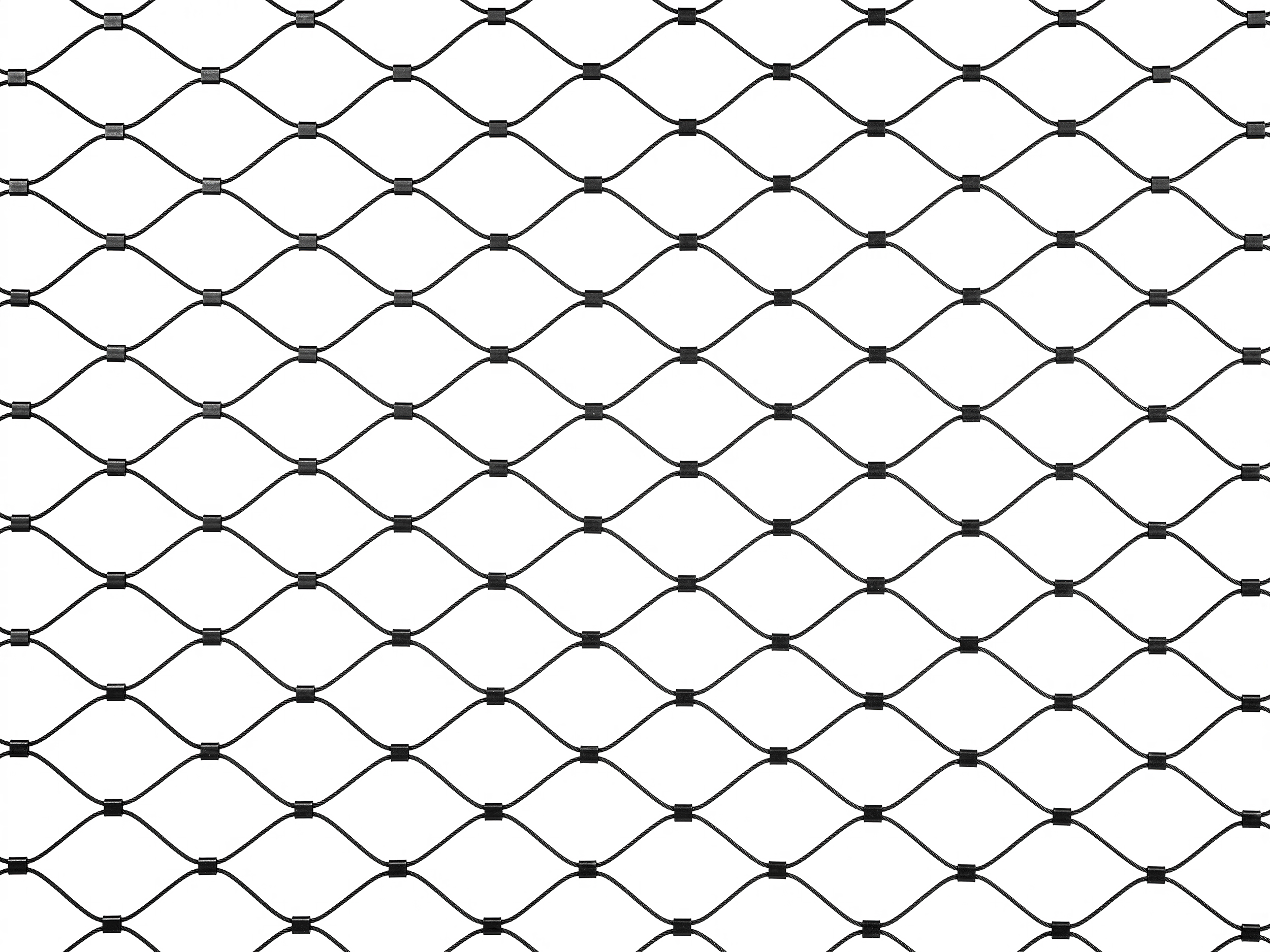

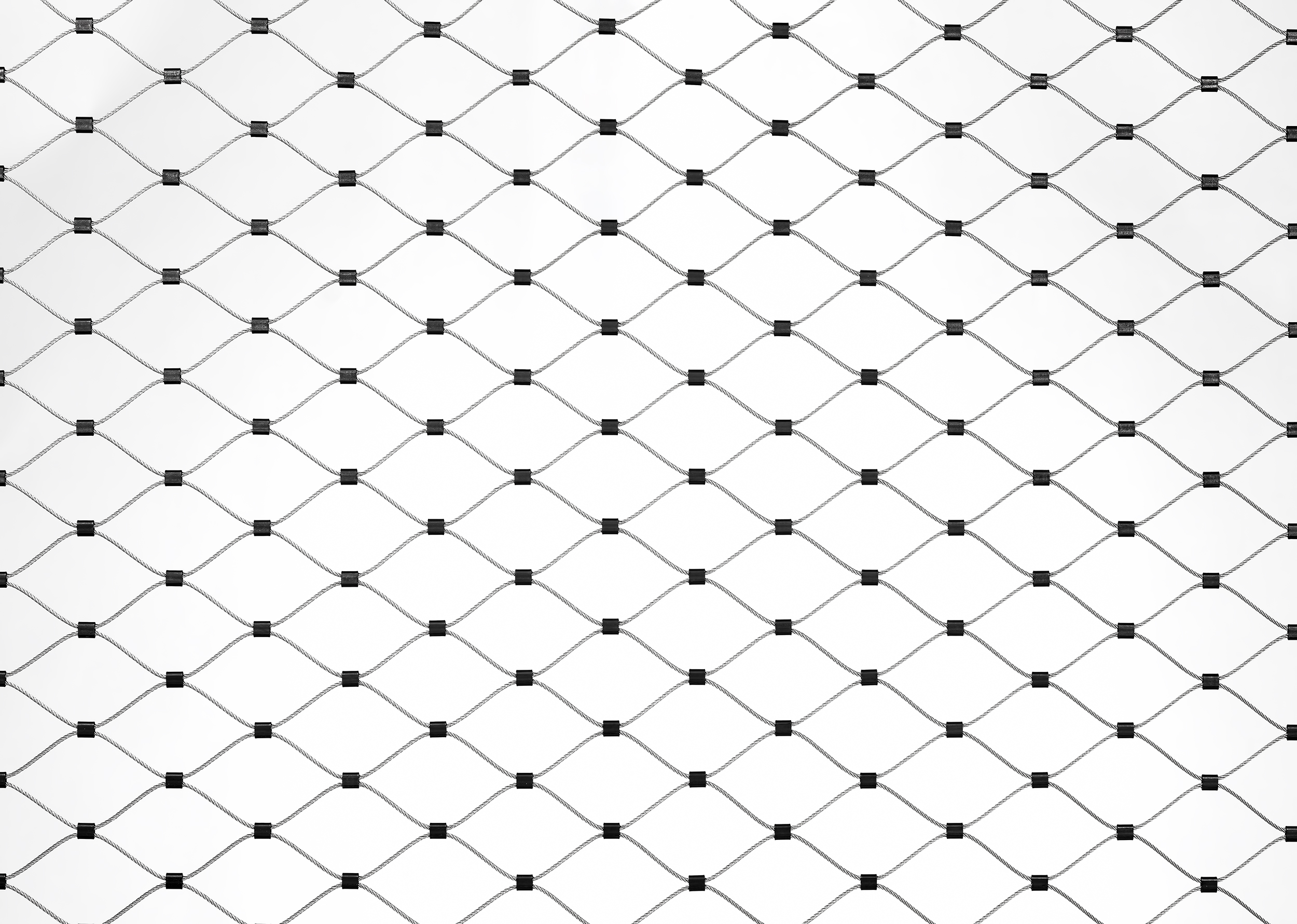

Unlike spectral and oxide coloring methods, wet painting technique

opens up a

broad spectrum of choices, allowing you to paint in numerous RAL

codes.

Move beyond the limitations of spectral and oxide coloring. Choose

from an

extensive palette of RAL codes to suit your design

preferences.

While wet painting adds a burst of color to I-NET® systems, it's important to

note that the may reduce the flexibility of the I-NET. For this

reason, the

wet painting process is ideal for frame systems within I-NET® configurations.

Lead time will increase approximately 3-4 weeks for additional

painting

process.

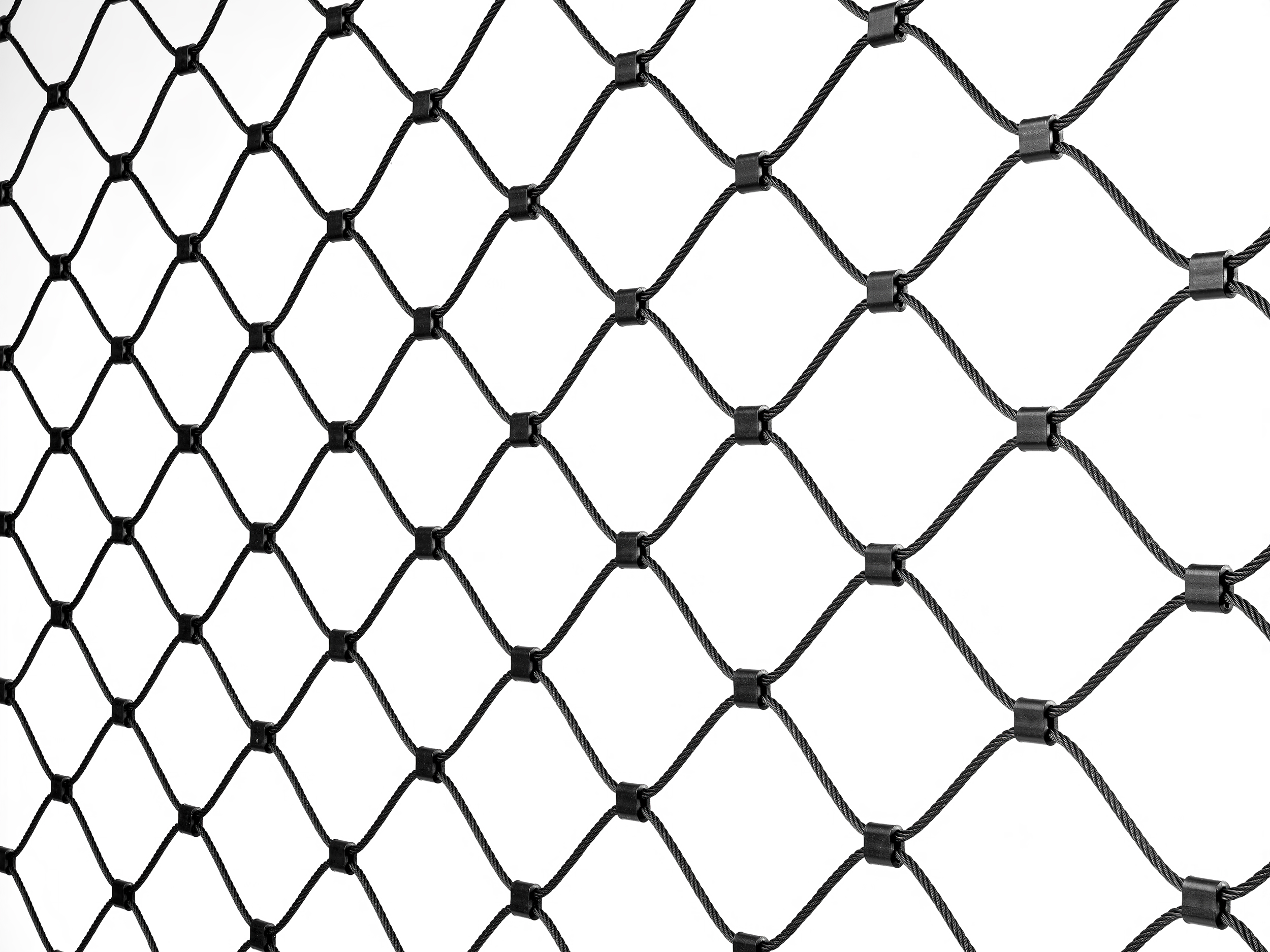

Process Description

Painting process is applied with a precise spray gun and a uniform flawless coverage is achieved with a very low paint loss. Following necessary pre-cleaning processes, the application begins with a primer base coat and continues with a top coat application at requested Ral color. Then the paint cured in the owen.

Advantages / disadvantages

- Versatile color options

- Reduce the flexibility of I-NET®

- Ideal for frame systems

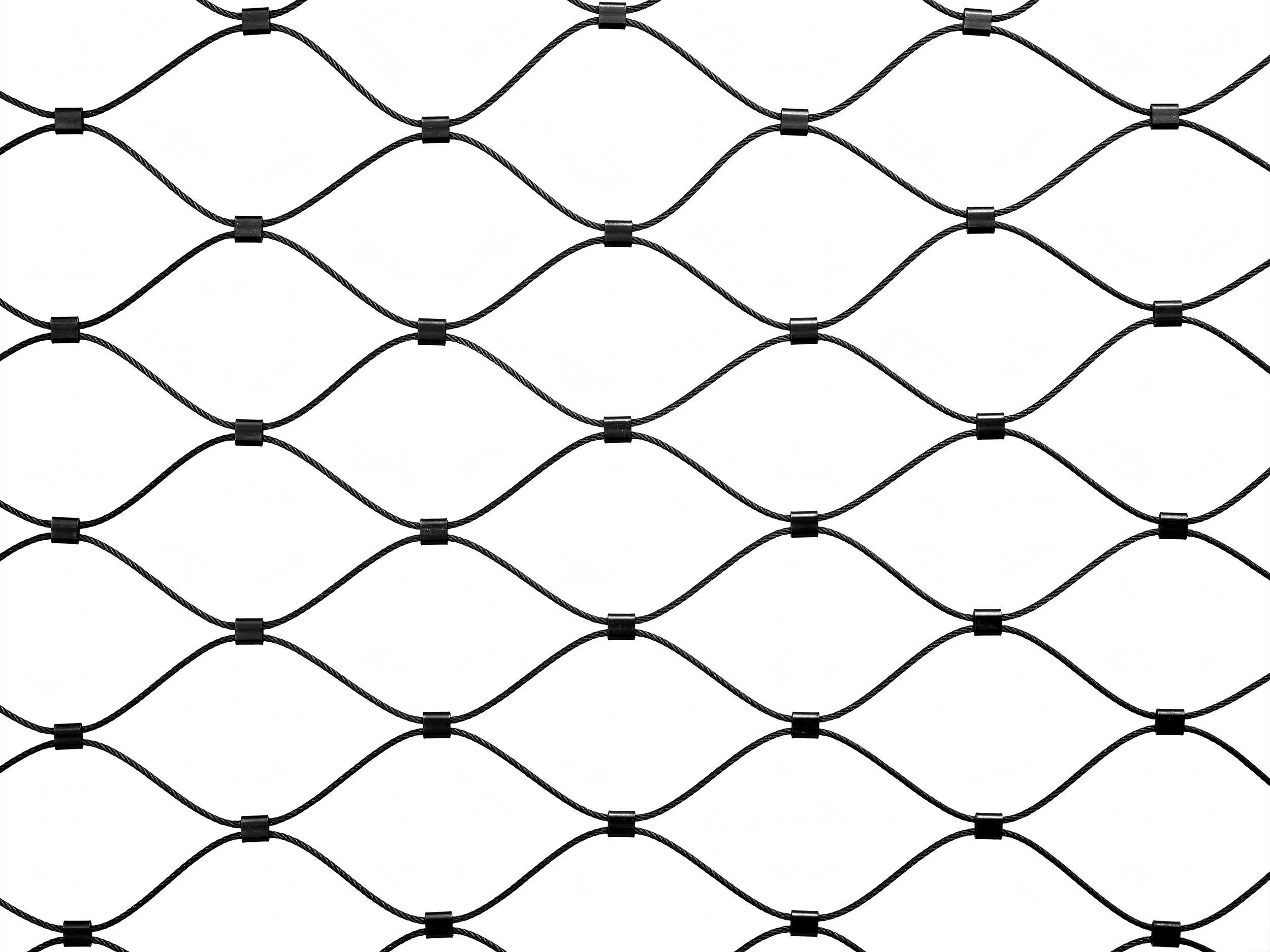

Application possibilities

-

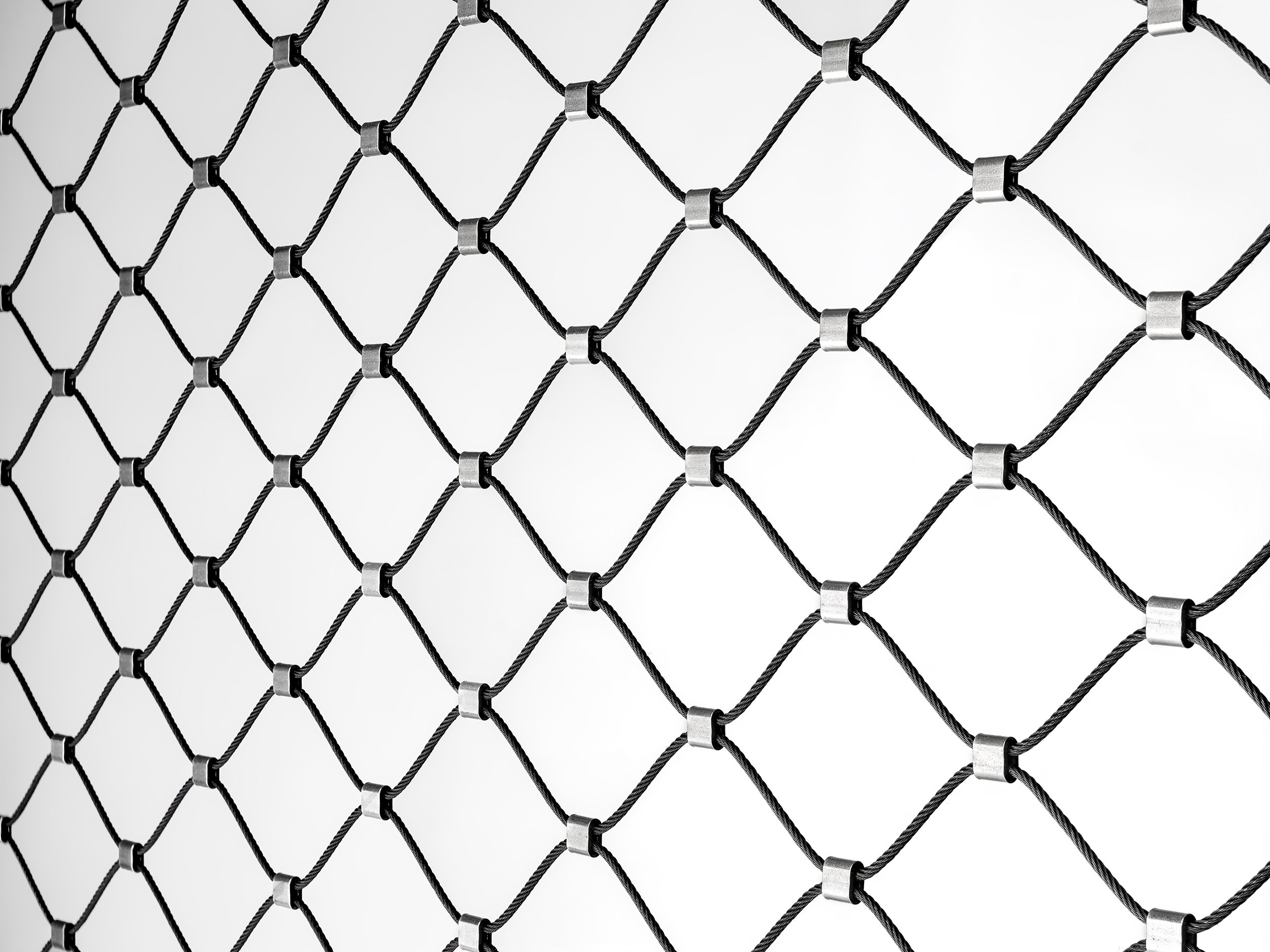

Coordinated Finishes

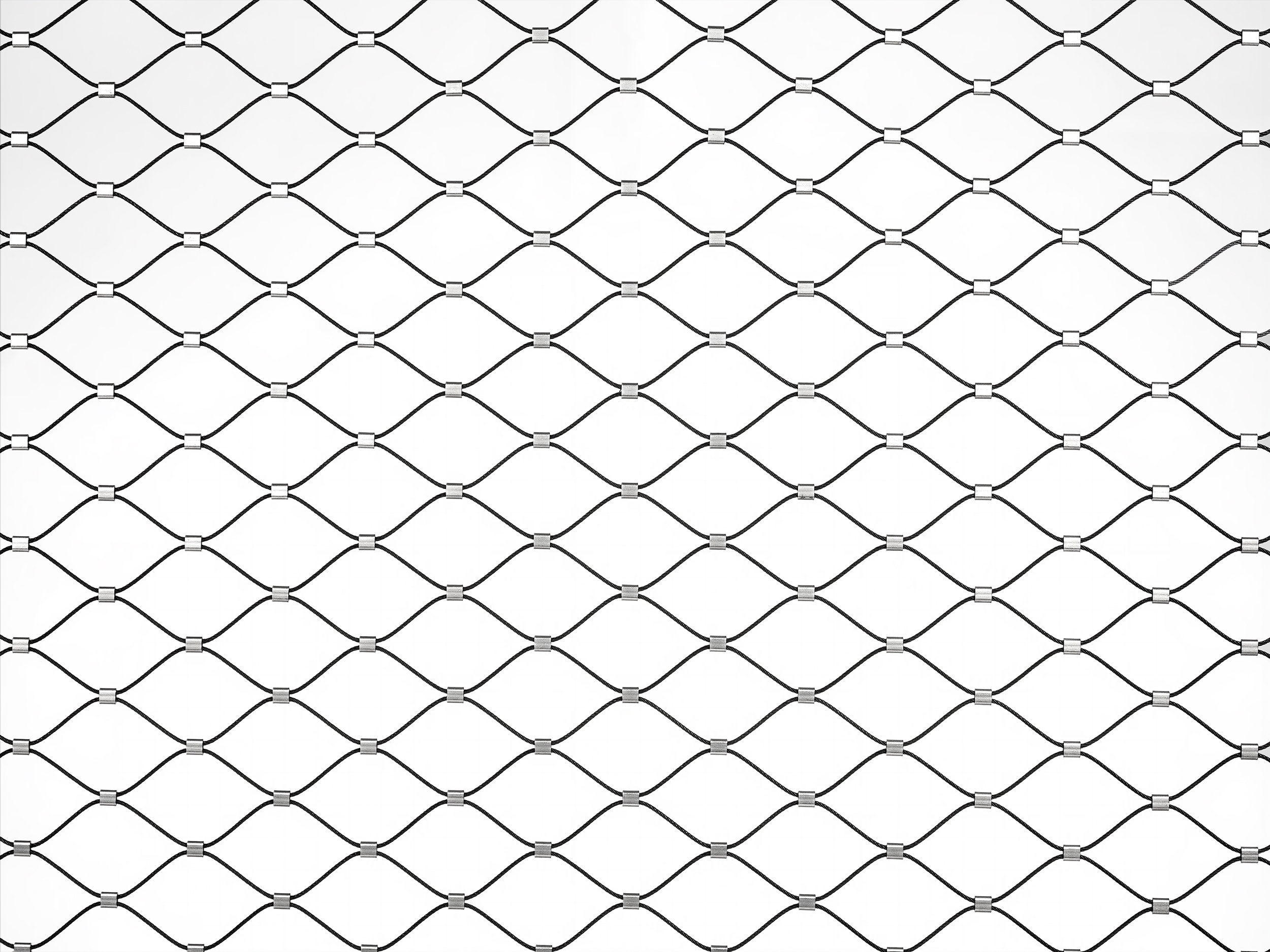

Achieve a seamless look by painting the I-NET® together with the frame, ensuring a unified aesthetic throughout the system. -

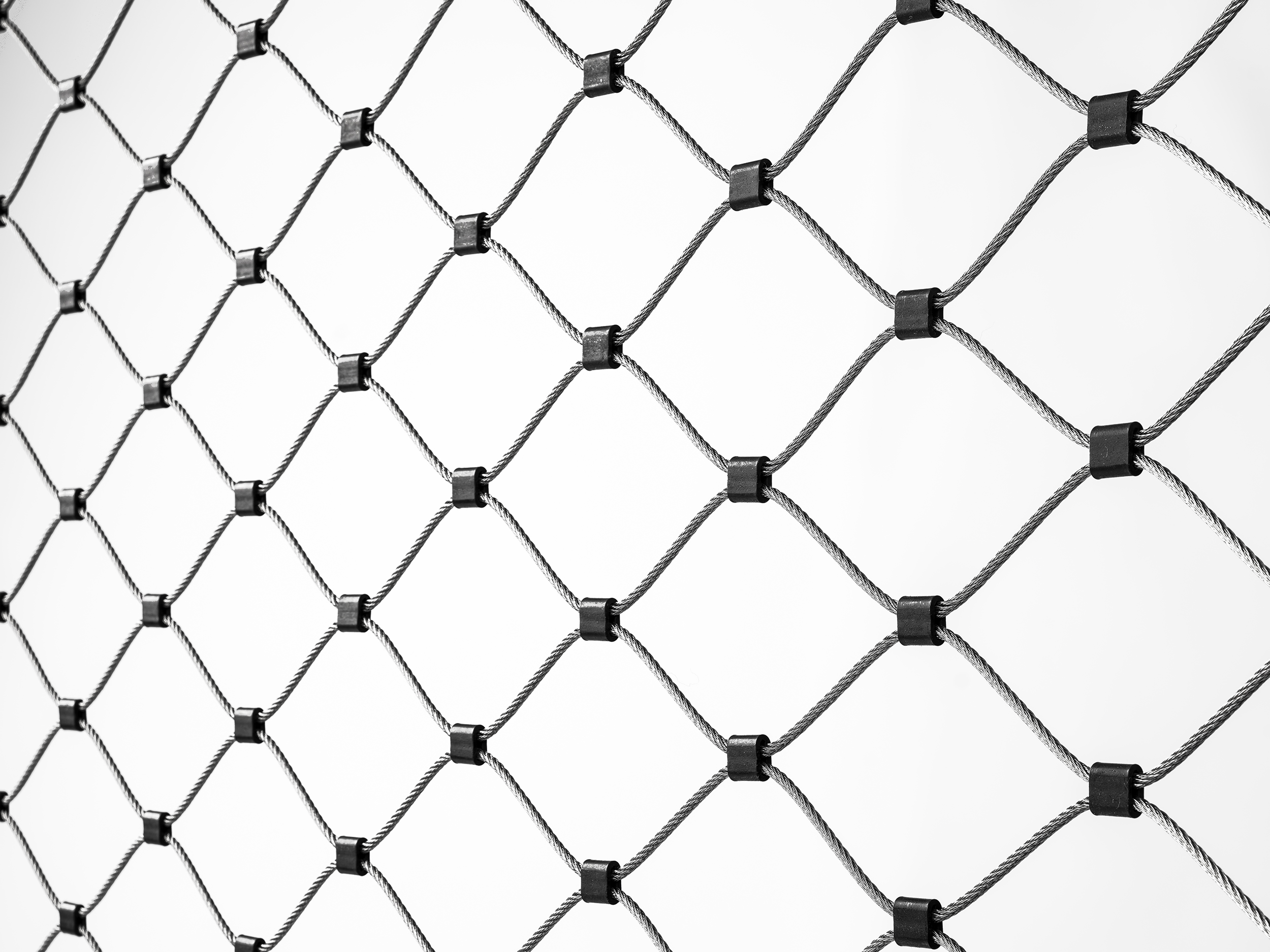

Contrast and Elegance

Option for a striking visual contrast by integrating natural stainless steel I-NET® into a meticulously painted frame system.