I-NET® Colours / Aesthetic Transformation of Stainless Steel Mesh

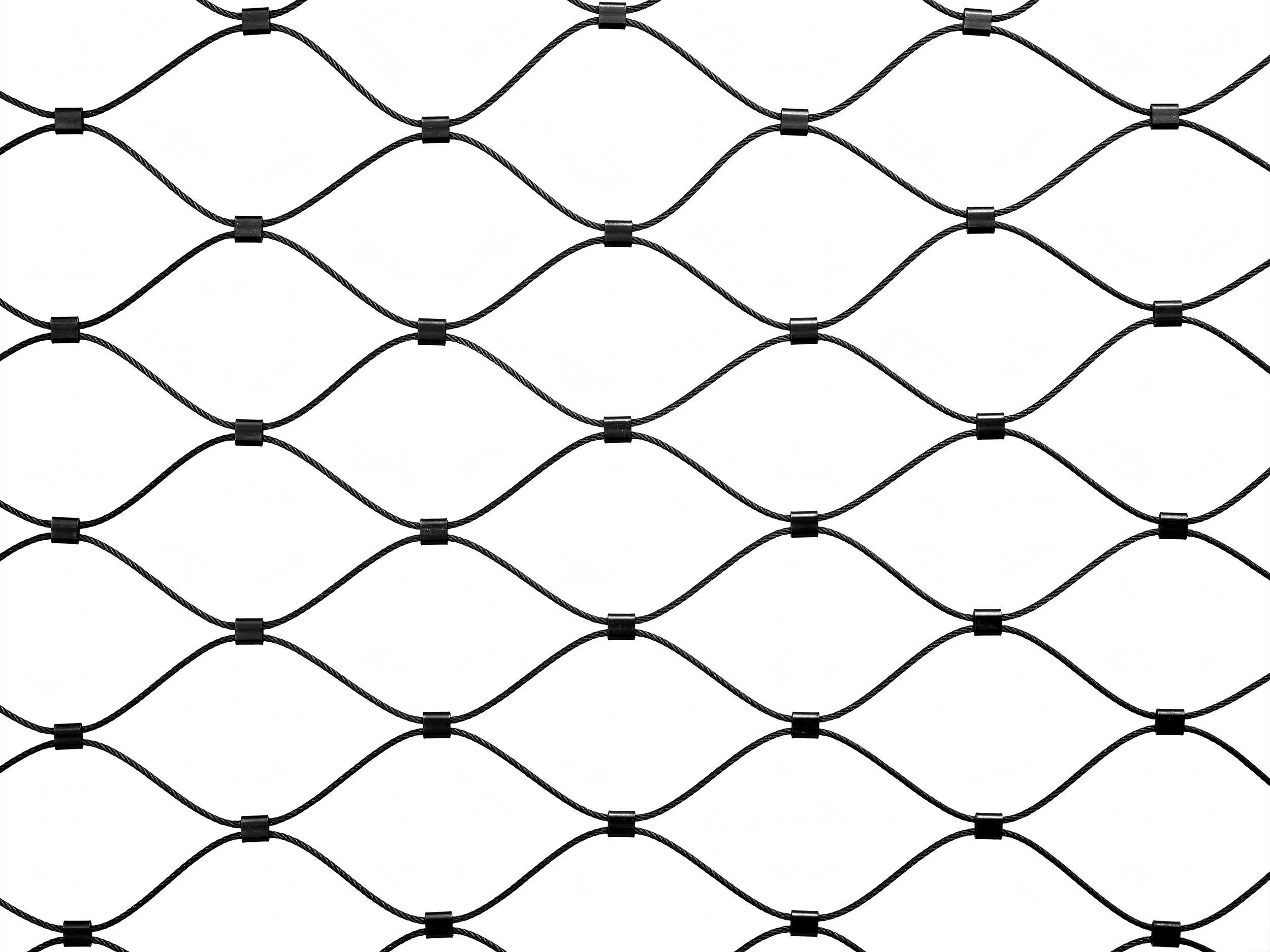

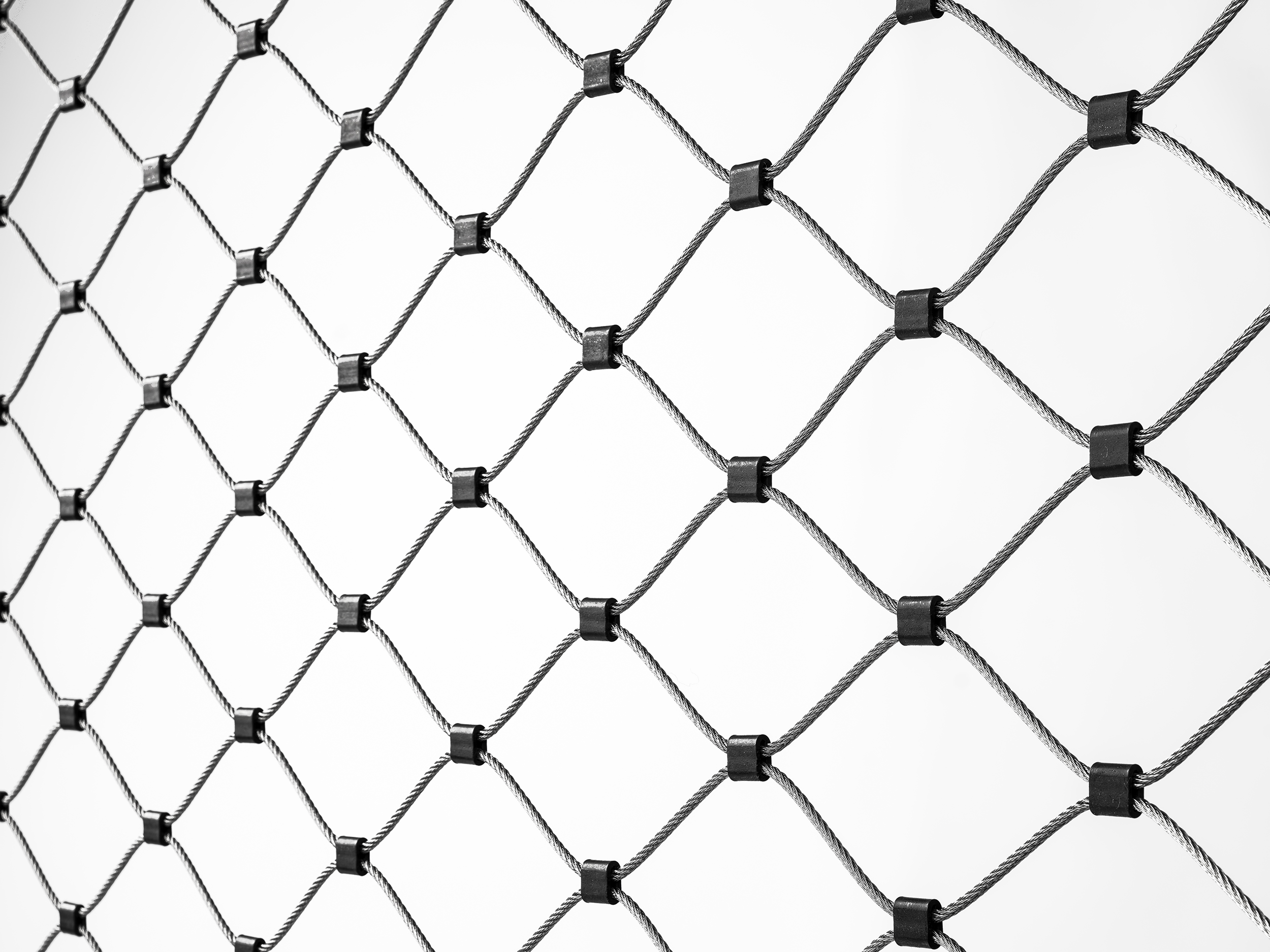

Spectral coloring alters the material's surface, enabling inoxnet® cable products to achieve elegant black hues while maintaining their exact shapes, flexibility, and long-lasting color durability.

Technical Detail

Technical Detail

Black oxidizing is often chosen to achieve an aesthetically pleasing matte black finish, in addition to enhancing the corrosion resistance of stainless steel products.

Technical Detail

Technical Detail

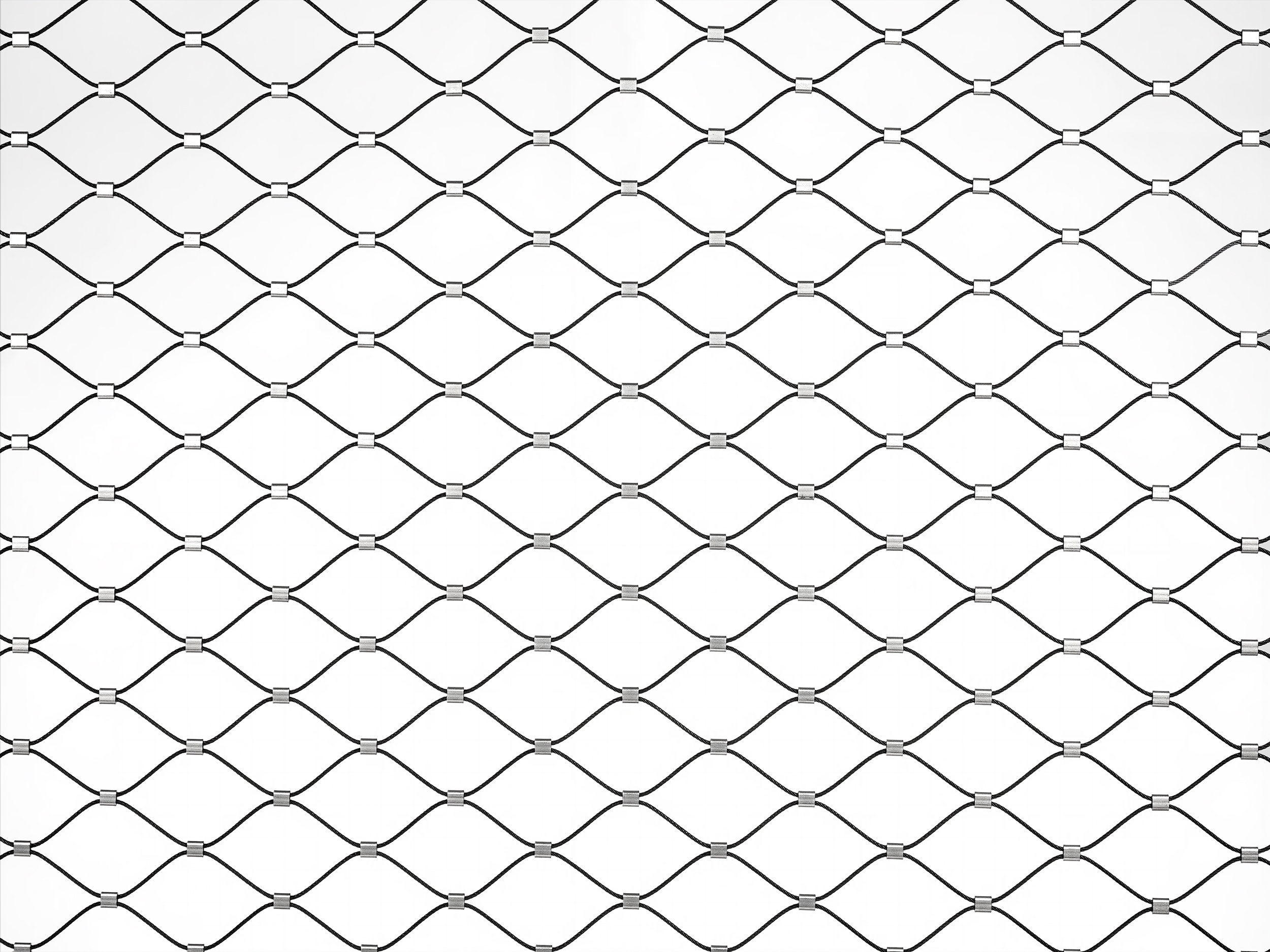

While offering a wide range of paint options in many RAL codes, the wet painting method is more ideal for frame systems due to its slight reduction in the flexibility of I-NET® cable meshes.

Technical Detail

Technical Detail